National Electric Co., is a company that has emerged as a pioneer in the industry by strictly focusing on innovation. Dealing in a wide range of Electromagnetic Hammers that are maintenance free and deliver superior performance compared to other conventional hammering systems, the company is known for its customer-centric approach that strives the specific requirements of clients. The Electromagnetic Hammers aid in preventing clogging and adhesion of powdery and granular materials within Spray Dryers, Cyclone, Hoppers, BINS, Powder conveying ducts, etc. The use of precision crafted components and high quality raw materials helps ensure that superior build quality is achieved. Tested along various quality parameters, the hammers comply with international standards and are offered to customers at prices that offer the best value for their money. Today, the company has become known as a leading Manufacturer and Supplier of Electromagnetic Hammers and the products offered by it are being used by renowned organizations in diverse sectors and have become known for their unrivaled build quality.

Product Introduction

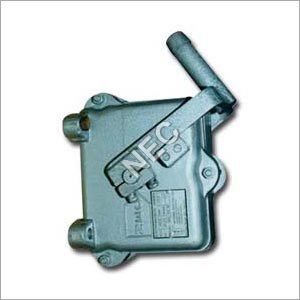

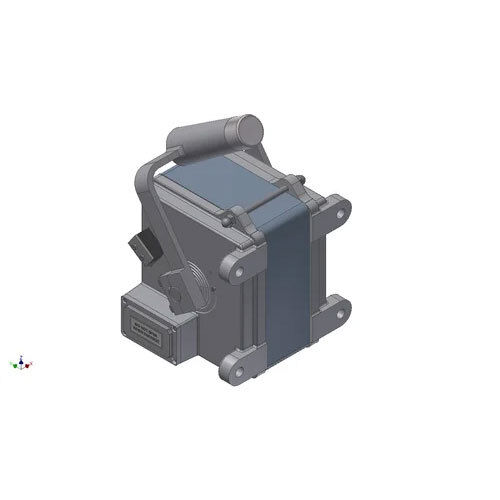

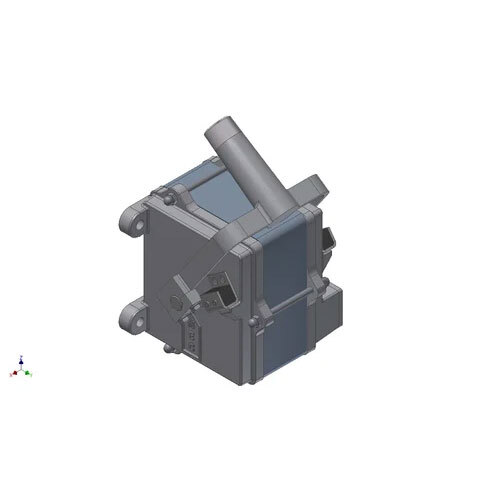

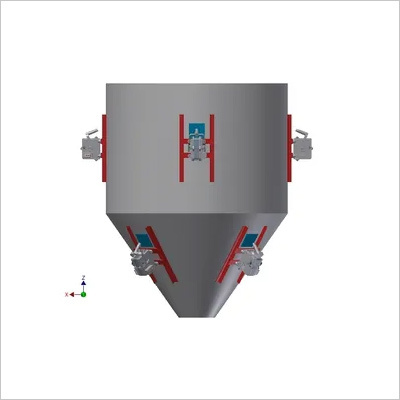

Electromagnetic Hammers are compact, maintenance free and are better than available conventional hammering systems specially designed for the application to eliminate sticking of the fine particles in the inner surface of

- Spray Drying Plants

- Cyclone Separators

- Powder Conveying Duct, etc.

Industries Served: Pharmaceutical & Biotech, Food & Beverage, Chemical Processing, Industrial Manufacturing, Metals & Minerals, Mining & Quarries, Power Generation, Pulp, Paper & Wood, and Petroleum Refining.

Electromagnetic Hammers are essentials to eliminate the side wall build up, agglomeration, bridging on interior surface and discharge plugging of powder in COAL BUNKERS, SPRAY DRYING PLANT, CYCLONE SEPARATORS, SILOS, BINS, etc.

Hammers help in the smooth operation of downside, conveying as well as collections equipment of the systems. Henceforth ensuring no sticking, low downtime, consistence quality, low losses, lump free products and smooth operation.

Applications:

Helps to solve solid flow problems

The Electromagnetic Hammer is designed to meet the challenges of a very broad base of applications. Some of the common problems with solid material movement includes:

NEC Electromagnetic Hammers are available in Flameproof and Weatherproof construction certified and approved by CMRI-Dhanbad

Control Panel

A control panel with sequential timer is required for the operation of hammering system, Industrial Vibrator,. Design of the control panel depends on the model and number of hammers to be installed on the chamber.

Industries

Helps Solve The Following:

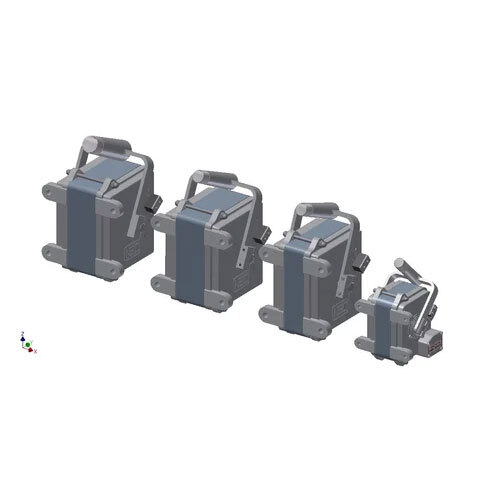

Selection Guide

Selection of Electromagnetic Hammer, Industrial Vibrator, Industrial Vibrator, depends on various factors such as plate thickness of chamber, design of stiffeners, type of product etc. however, as a general guide line

Number of hammers depends on surface area of chamber.

Click To Download PDF