Electromagnetic Hammers

Price 9500.00 INR/ Piece

Electromagnetic Hammers Specification

- Material

- MS

- Application

- Hammer

- Product Type

- Electromagnatic Hammer

- Magnet Category

- Electromagnets

- Magnet Type

- Electromagnatic

- Shape

- U-Shape

- Color

- Any

Electromagnetic Hammers Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Pieces Per Day

- Delivery Time

- 2 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS per customer;s request

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India, Dadra and Nagar Haveli, North India, Tamil Nadu, Andaman and Nicobar Islands, Delhi, Goa, Arunachal Pradesh, Haryana, Assam, Tripura, West India, Chhattisgarh, South India, Sikkim, Jammu and Kashmir, Odisha, Telangana, Kerala, Jharkhand, Rajasthan, , Gujarat, Chandigarh, Himachal Pradesh, Karnataka, Pondicherry, Central India, Andhra Pradesh, Uttarakhand, Bihar, Punjab, West Bengal, Lakshadweep, Manipur, Madhya Pradesh, Uttar Pradesh, Maharashtra, Mizoram, Nagaland, Daman and Diu, East India, Meghalaya

- Certifications

- ISO

About Electromagnetic Hammers

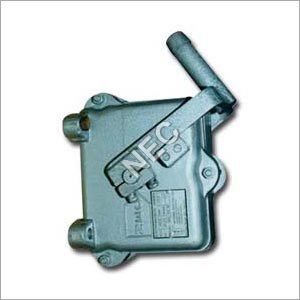

Electromagnetic Hammers

The Electromagnetic Hammers offered by us are the preferred choice in a wide range of industries such as chemical & pharmaceutical, ceramic, cement and mining etc. This can be primarily attributed to their unmatchable features such as compact nature, robust design and many more. The Electromagnetic Hammers are specifically designed for the purpose of eliminating and also preventing the common occurrence of sticking of finer particles in the inner surfaces of cyclone separators, spray drying plants etc.

Additional information:

-

These are also ideal for removing the distortion caused on a material due to welding through bending or stretching the material to the desired contour

-

These work flawlessly in all weather conditions

-

These have optimal tolerance to other natural occurrences such as moisture and UV rays

- Model NEC-EH-S for the plate thickness less then 2 mm.

- Model NEC-EH-50 for the plate thickness of 2 to 3 mm.

- Model NEC-EH-75 for the plate thickness of 6 to 8 mm.

- Model NEC-EH-75B for heavy impact.

Flameproof & Weatherproof Electromagnetic Hammer

- Model NEC-FEH -50 for the plate thickness of 2 to 3 mm.

- Model NEC-FEH-75 for the plate thickness of 6 to 8 mm.

Technical specification

|

Model |

Volt |

Pulse Current (amp) |

Power Consumption @ 10 strokes/min |

Mpact Force |

Weight (kg) |

|---|---|---|---|---|---|

|

NEC - EH - S |

230 VAC |

2.0 |

.001 units/hr. |

2.0 Kgf |

7 kg |

|

NEC - EH - 50 |

415 VAC |

4.0 |

.003 units/hr |

3.5 Kgf |

15 kg |

|

NEC - EH - 75 |

415 VAC |

6.0 |

.045 units/hr. |

5.5 Kgf |

20 kg |

|

NEC - EH - 75B |

415 VAC |

10.5 |

.065 units/hr. |

7.0 Kgf |

25 kg |

|

NEC - EH - 75 HI |

415 VAC |

30.0 |

.090 units/hr. |

10.5 Kgf |

30 kg |

Specification

|

Finishing |

Polished |

|

Frequency |

50 Hz |

|

Power Source |

Electric |

|

Pulse Current (amp) |

2-6 |

|

Volt |

230 VAC |

|

Weight |

6 Kg |

FAQs

Q1: What is an electromagnetic hammer?

A1: An electromagnetic hammer is a tool used in metalworking that uses electromagnetic forces to generate powerful impacts. It is typically used to punch, form, or shear metal.

Q2: How does an electromagnetic hammer work?

A2: An electromagnetic hammer consists of an electromagnet that is attached to a piston or plunger. When the electromagnet is energized, it creates a powerful magnetic field, which causes the piston or plunger to move rapidly, generating a powerful impact.

Q3: What are the benefits of using an electromagnetic hammer?

A3: The main benefit of using an electromagnetic hammer is that it can generate much higher forces than traditional mechanical hammers. This makes them ideal for forming and shearing metal, as well as punching holes in sheet metal. Additionally, they are more precise and can be controlled more easily than traditional mechanical hammers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electromagnetic Hammers Category

Hopper Vibrators

Price 10000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage & Applications : Industrial

Product Type : Vibrator

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry